Building a house is a very serious matter. Taking into account all the nuances will ensure the strength and reliability of the structure, its durability. For example, if you plan to build a building on several floors, it is better to use hollow core slabs. Naturally, it is better to understand this material as much as possible.

So, hollow plates are special panels,made of reinforced concrete. They have a strictly specified thickness and dimensions. They can be used in both low-rise and high-rise buildings. It should be noted that today this material is very in demand. In this case, it does not matter at all from what exactly the construction will be erected: brick, blocks, concrete.

Naturally, hollow plates have someadvantages and disadvantages, which we will consider later. It is very important to buy material from reliable suppliers. The fact that its quality depends on the stability and strength of the building, as well as your personal safety.

So, hollow plates have such advantages:

Classify hollow-core reinforced concrete slabs as follows:

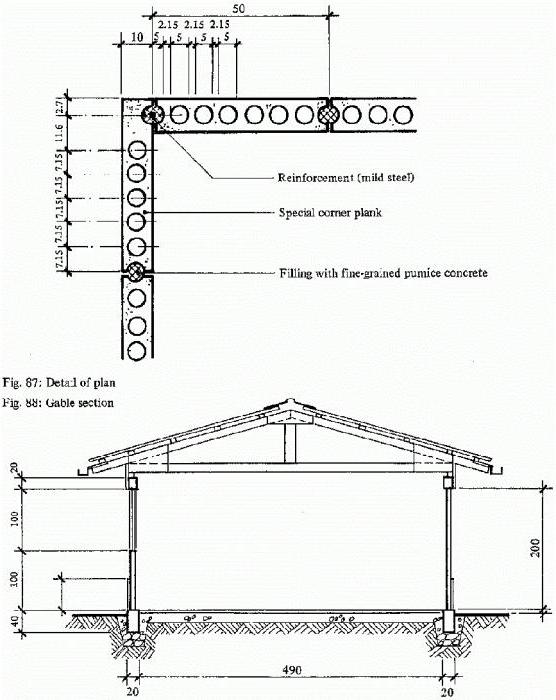

1. Products intended for support from two, three or four sides. They have a relatively small thickness (22 cm) and round voids (diameter 15, 14 or 12.7 cm).

2. Plates of hollow reinforced concrete with round voids. The thickness of such products is 26 cm. At the same time they can rest on two, three or four sides. The void diameter is 16 or 18 cm.

3. Panels that have voids in the form of a pear. They usually rely on two sides. The thickness of such an article is about 26 cm.

If you need to know the dimensions according to GOST, plateshollow, in general, have such dimensions: width - 1.8 m, length - from 1.6 to 12 m, height - 16-40 cm. From the presented indicators, the cost of panels also largely depends.

A plate is made using onlyquality raw materials. For example, in work plants use only two types of concrete: lightweight, but dense structural, as well as silicate (heavy). Please note that the quality of raw materials is determined by the state standard. Naturally, not only concrete but also reinforcement is used in production. It can be ordinary or strenuous.

In order for the plates to work well for shearall planes, they should be made with grooves or grooves. They are usually placed on the side faces. If the panels rely on only 3 or 2 sides, then they must necessarily be strained. At the same time, the ends must be reinforced.

So, the plates are hollow (you already know their sizes)must be properly installed. You can not do this with your hands, so you will need special equipment - a mobile crane. Before starting the installation, it is imperative to check whether the walls in the horizontal plane are even. If there is a problem with the level, then your plate will be skewed. This will cause your rooms to have an uneven floor, or the cracks will quickly appear in the slab, which will only increase with time. At the same time, the cost of heat increases, condensation begins to collect in the room, and it is very difficult to make a finishing on the damaged surface.

During construction, it is important to calculate the load,which will be provided on the hollow plates. The dimensions of the product also depend on this. That is, the more pressure is applied to the panel, the thicker it should be.

It is especially important to take into account these nuances,if your house is built in the area where seismic activity is fixed. When buying, pay attention to whether the new cooker. Products that were second-hand, it is better not to buy.

In order to build a reliable house, youuse plates hollow. Dimensions (GOST 9561-91 strictly regulates the dimensions and composition) depend on the total area of the structure, as well as the anticipated load of the roof (upper floors). Such panels are used for the construction of roofs, load-bearing structures, and also as partitions between floors.

The use of such products also has certainfeatures. For example, if a slab is used to build an attic space, it must be insulated. Improper transport of the material may result in cracking or damage. Therefore, during transportation between the panels should be laid wooden bars. He will not let the plates touch each other.

If you need to strengthen the product, you can additionallyuse the armature. It is laid from the bottom of the panel between the voids. If the panel has been damaged slightly, a defect can be eliminated by yourself. It will not reduce the functionality of the product as a whole.

As you can see, the materials are usedhigh demand and are used in the erection of almost any type of structure. Naturally, you just need to choose, calculate and mount the hollow plates correctly.

</ p>